| Bar Soaps |

| Liquid Hand Soap |

| Body Wash |

| Laundry Detergent |

| Vehicle Wash/Fleet Washing | Bus Wash | Truck Wash Soaps | Aircraft Soap | Soaps & Car Wash Products |

Bar Soaps

| |||||||||||||||||||||||||||||||||||||||||||||

|

What is soap? What are the types of soaps? What is the Difference between Soap and Detergent? What is the difference between detergents and disinfectants? What are detergents? What other chemicals are in detergents? What effect do detergents have on the environment? How Do Detergents Clean? | |||||||||||||||||||||||||||||||||||||||||||||

|

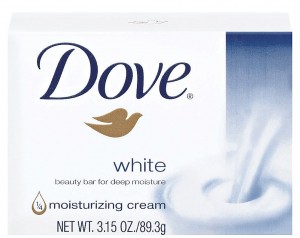

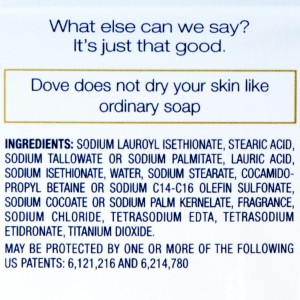

What is soap? In chemistry, soap is a salt of a fatty acid. Consumers mainly use soaps as surfactants for washing, bathing, and cleaning, but they are also used in textile spinning and are important components of lubricants. Water soluble compound made by a reaction (called saponification) between caustic soda (sodium hydroxide) or caustic potash (potassium hydroxide) with animal and/or vegetable fats (oils). Soap has surface active properties (see surfactant) to wet a greasy (oily) soiled surface and suspend the oil and dirt in the water for rinsing off. Synthetic soaps (called detergents) are made from petroleum-based products, and some heavy soaps (made from lead, zinc, or other heavy-metal compounds) are water-insoluble and are used mainly in lubricating greases. What is the Difference between Soap and Detergent? An example of a soap is sodium palmitate: CH₃(CH₂)₁₄-COO⁻ Na⁺ An example of a detergent is sodium lauryl sulfate: CH₃(CH₂)₁₂-OS(O)₂-O⁻ Na⁺ Detergents Sodium laureth sulfate and ammonium lauryl sulfate are two common detergents in liquid soaps. Both work by dissolving oil and dirt to clean them from your hands. Sodium laureth sulfate, or SLS, is also an emulsifier that helps to combine all the ingredients in the soap. GENERAL CHARACTERISTICS OF SOAPS 1. Are obtained from vegetable or animal oils. 2.Because of being natural they do not effect human body. 3. Structured by easily broken down natural means. 4. Do not cause water pollution. 5. There is no damage to the environment. 6. Over time, they lose the cleaning power. 7. The metal ions in hard water to form precipitate. 8. They damage clothing. 9. More effective with warm water. 10. Used for thousands of years. GENERAL CHARACTERISTICS of DETERGENTS 1. Petroleum derivatives and can be obtained synthetically. 2. They affect the human body. 3. Easily biologically degradable. 4. Cause water pollution. 5. Cause environmental pollution.v 6. There are special formulas for different purposes. 7. Ions in hard water are affected very little. 8. Even in cold water they clean well. 9. They do not damage clothing a lot.. 10. Widely used in the last 50-60 years. Let’s take a look at the ingredients listing for a Dove White Moisturizing Beauty Bar.

Sodium Cocoyl Isethionate, Stearic Acid, Sodium Tallowate, Water, Sodium Isethionate, Coconut Acid, Sodium Stearate, Cocamidopropyl Betaine, Sodium Cocoate or Sodium Palm Kernelate, Fragrance, Sodium Chloride, Titanium Dioxide, Tetrasodium EDTA, Trisodium Etidronate.

*What is a surfactant? A surfactant is a cleansing agent that are used for either cleaning the skin and/or hair as well as emulsifiers in products. So to put it basically, surfactants make water wetter, emulsify or solubulize body oils and suspend dirt and grime. Most surfactants also add foaming and lathering characteristics to products containing them. |

|

Components Modern detergent formulations – the entire product vs just the surfactant – contain several components. Three main ingredients are builders (50% by weight, approximately), the alkylbenzenesulfonate surfactant (15%), and bleaches (7%). Builders Bleach Enzymes Other ingredients Builders Builders are water softeners. These chemical compounds are agents that remove calcium ions by complexation or precipitation. Typical builders are sodium carbonate, complexation agents, soap, and zeolites. They function by sequestering or precipitating the problematic ions. One of the most common builders is sodium triphosphate, which is used on very large scale for this application. Bleach The main targets of bleaches are of vegetable origin and include chlorophyll, anthocyanin dyes, tannins, humic acids, and carotenoid pigments. Most bleaches in laundry detergents are oxidizers, e.g., sodium perborate or sodium hypochlorite. In addition, other agents are added as "bleach activators", to enhance the effectiveness of the bleaching agent; a popular one is tetraacetylethylenediamine. Enzymes The amounts of enzyme can be up to about 2% by weight of the product. These agents are required to degrade recalcitrant stains composed of proteins, fats, or carbohydrates. Each type of stain requires a different type of enzyme, i.e., protease for proteins, lipases for greases, and amylases for carbohydrates. Other ingredients Many other ingredients are added depending on the specific application. Such additives modify the foaming properties of the product by either stabilizing or counteracting foam. Other ingredients increase or decrease the viscosity of the solution, or solubilize other ingredients. Corrosion inhibitors counteract damage to washing equipment. "Dye transfer inhibitors" prevent dyes from one article from colouring other items. "Antiredeposition agents" are used to prevent fine soil particles from reattaching to the product being cleaned. Carboxymethyl cellulose is used for this purpose. A number of ingredients affect aesthetic properties of the item to be cleaned or the detergent itself before or during use. These agents include optical brighteners, fabric softeners, and colourants. A variety of perfumes are also components of modern detergents, provided that they are compatible with the other components and do not affect the colour of the cleaned item. The perfumes are typically a mixture of many compounds, a popular component being cyclohexyl salicylate, which is related to oil of wintergreen.

Liquid Bars |

Powder detergent

Roma Phosphate Free Economical and effective. For all fabrics. Available in: 4 bags 11 Lbs 0.3 oz - 10 bags 4 Lbs. 6.5 oz 18 bags 2 Lbs. 3.2 oz - 36 bags 1Lb. 1.6 oz 72 bags 8.83 oz Listed ingredients are: Cleaning Agent - Lineal Anionic Surfactant Water Softener - Aluminosilicates and silicate Soil Suspending Agent - C.M.C Optical Brightener Perfume Roma comes packaged in a 1.1, 2.2 or 4.4 pound plastic bag. http://www.lacorona.com.mx/ |

Liquids |

Liquid Gel form |

|

|

|

|

| What are the types of soaps? |

| Laundry soaps |

| Kitchen soaps |

| Personal soaps |

| Cleaning soaps |

| Car washes, auto centers soaps |

|

Soaps & Detergents: Manufacturing What is soap made of? Soaps are sodium or potassium fatty acids salts, produced from the hydrolysis of fats in a chemical reaction called saponification. Saponification Usually, a process by which triglycerides are reacted with sodium or potassium hydroxide to produce glycerol and a fatty acid salt, called 'soap'. Lipids that contain fatty acid ester linkages can undergo hydrolysis. This reaction is catalyzed by a strong acid or base. Saponification is the alkaline hydrolysis of the fatty acid esters. Soaps and detergents are very similar in their chemical properties. However, there is a significant difference between them; soaps are produced from natural products, and detergents are synthetic, or man-made. General Questions Under which set of conditions are soaps preferable to detergents? 1. A. in hard, mineral rich water B. in soft water that is relatively free of dissolved minerals C. in environmentally sensitive areas as an agent to launder clothing D. as a laundering agent for clothing, as opposed to a product needed to cleanse the body Answer: B. in soft water that is relatively free of dissolved minerals Clothing stained with oil cannot be effectively cleaned with water alone. It is well known that oil does not mix well with water. Why is the addition of soap or detergent helpful in removing a greasy stain? 2. A. Soap molecules have a hydrophillic end that adheres readily to oil. B. The hydrophillic end of the soap repels oil. C. The hydrophobic end of the soap molecule attracts and removes the oil. D. The hydrophobic end of the soap molecule is attracted to water, making the soap mix well in water. Answer: C. The hydrophobic end of the soap molecule attracts and removes the oil. As stated in paragraph 6 in the passage, soap is made form a combination of chemicals. One of these is fatty acids. In order to get fatty acid, one hydrogen atom combines with two oxygen atoms and one carbon atom to get a carboxylic acid molecule that is combined with straight chain carbon and hydrogen molecules. What is the maximum amount of carboxylic acid molecules that can be made with 1200 Hydrogen atoms, 2000 Oxygen atoms, and 1500 Carbon atoms? 3. A. 1200 B. 1500 v C. 2000 D. 1000 Answer: D. 1000 What is the maximum amount of difference in calcium carbonate between the softest soft water and the softest hard water? ( in mg/L). 4. A. 150 B. 75 C. 300 D. 225 Answer: A. 150 Which of the following statements is true of both soap and detergent? 5. A. They are made from natural products. B. They are surfacants. C. They are less harmful to human skin. D. They are biodegradable. Amswer: B. They are surfacants. What is the meaning of the word hydrophobic? 6. A. attracted to water B. attracted to soap C. repelled by water D. repelled by oil Answer: C. repelled by water Which of the following statements does NOT support the main idea of this passage? 7. A. Both soaps and detergents share a critical chemical property. B. Soap is made from natural products and detergents are made from synthetic products. C. Soaps and detergents are frequently used in our daily lives. D. Romans discovered the cleaning power of soap accidentally. Answer: A. Both soaps and detergents share a critical chemical property. All of the following statements are true of soap EXCEPT: 8. A. it is more powerful than synthetic detergent B. it is made from natural products C. it does nto rinse out as well as detergent on clothes D. it is biodegradable Answer: A. it is more powerful than synthetic detergent |

|

Bar Soaps Powder Detergents Liquid Detergents Packaging |

|

Soap and Detergent Manufacture Industry Overview The soap and detergent manufacturing industry includes about 700 companies with combined annual revenue of $17 billion. (Pending, Asia, Middle East, Africa, Europe) Products, Operations & Technology Major products include laundry detergent, soap, dishwashing detergent, and toothpaste. Laundry detergent accounts for 40 percent of industry revenue, soap for 20 percent, and dishwashing detergent for 15 percent. Laundry detergent comes in powder, bars or liquid form, and may contain bleach additives or color brighteners. Dishwashing detergent comes in powder, liquid, or gel form. Soap comes in bars or liquids, and may have moisturizing, antibacterial, or deodorant benefits. Companies in the commercial sector may also sell dispensing equipment and provide related training. Detergent production starts by combining liquid and dry ingredients. Spray drying produces powder detergents by spraying the liquid mixture through nozzles under high pressure to create small droplets. The droplets fall through hot air and dry into hollow granules. Heat-sensitive ingredients, such as bleach or fragrance, are added after spray drying. Agglomeration produces higher density detergent powders by using a liquid binder and a different mixing process known as "rolling" or "shear mixing." Dry blending mixes dry raw materials with small quantities of liquids. Detergents are packaged in cartons, bottles, pouches, or bags. Soap production starts by heating fatty acids or fats and oils, and combining them with alkali, such as sodium or potassium. The process, known as saponification or neutralization, produces a combination of soap and water (known as neat soap) plus glycerin, which can be resold. Neat soap is converted into dry soap pellets through vacuum drying. An amalgamator mixes pellets with fragrances and colors. Rolling mills and refining plodders refine the mixture to achieve uniform texture. The final mixture is extruded, cut into bars, and stamped into shapes in a soap press. Soap bars are wrapped and packaged into single or multiple packs. Soaps and detergents are made of surfactants or surface-active agents, chemicals that help water soak and clean surfaces. Many surfactants are petroleum-based. Oleochemicals are surfactants derived from natural fats and oils. Soap reacts with minerals in hard water, diminishing cleaning properties. Builders boost the efficiency of surfactants by counteracting hard water, emulsifying oil and grease, and preventing soil from redepositing. Phosphates, an environmentally controversial chemical, are a commonly used builder. Raw materials include surfactants, solvents, phosphates, silicates, alkalis, salts, and perfumes. Suppliers include major chemical manufacturers like Shell Chemical and Dow. P&G has a separate business unit that manufactures key chemicals as part of a global supply network. Packaging is about 20 percent of product costs, and includes bags, boxes, bottles, tubes, and labels. Companies may rely on or provide third-party contract manufacturing services. Large companies may own multiple plants. Soap and detergent manufacturing is highly automated, and involves significant capital investment in plants and equipment. Computers control production equipment and inventory management. Many companies use electronic data interchange (EDI) to optimize the purchasing process. Due to the high level of automation, the average plant has fewer than 20 employees. R&D involves creating, testing, and improving product formulation, and evaluating environmental compatibility. Technological advances have reduced the amount of product needed, thereby reducing the amount of packaging. Micro encapsulation technology allows manufacturers to deliver unstable ingredients, like vitamin C, through soap to the skin. Manufacturers also test new enzymes and bleaches that improve the efficacy of products. Water, the liquid commonly used for cleaning, has a property called surface tension. In the body of the water, each molecule is surrounded and attracted by other water molecules. However, at the surface, those molecules are surrounded by other water molecules only on the water side. A tension is created as the water molecules at the surface are pulled into the body of the water. This tension causes water to bead up on surfaces (glass, fabric), which slows wetting of the surface and inhibits the cleaning process. You can see surface tension at work by placing a drop of water onto a counter top. The drop will hold its shape and will not spread. In the cleaning process, surface tension must be reduced so water can spread and wet surfaces. Chemicals that are able to do this effectively are called surface active agents, or surfactants. They are said to make water "wetter." Surfactants perform other important functions in cleaning, such as loosening, emulsifying (dispersing in water) and holding soil in suspension until it can be rinsed away. Surfactants can also provide alkalinity, which is useful in removing acidic soils. Surfactants are classified by their ionic (electrical charge) properties in water: anionic (negative charge), nonionic (no charge), cationic (positive charge) and amphoteric (either positive or negative charge). Soap is an anionic surfactant. Other anionic as well as nonionic surfactants are the main ingredients in today's detergents. Now let's look closer at the chemistry of surfactants. SOAPS Soaps are water-soluble sodium or potassium salts of fatty acids. Soaps are made from fats and oils, or their fatty acids, by treating them chemically with a strong alkali. First let's examine the composition of fats, oils and alkalis; then we'll review the soapmaking process. Fats and Oils The fats and oils used in soapmaking come from animal or plant sources. Each fat or oil is made up of a distinctive mixture of several different triglycerides. In a triglyceride molecule, three fatty acid molecules are attached to one molecule of glycerine. There are many types of triglycerides; each type consists of its own particular combination of fatty acids. Fatty acids are the components of fats and oils that are used in making soap. They are weak acids composed of two parts: A carboxylic acid group consisting of one hydrogen (H) atom, two oxygen (O) atoms, and one carbon (C) atom, plus a hydrocarbon chain attached to the carboxylic acid group. Generally, it is made up of a long straight chain of carbon (C) atoms each carrying two hydrogen (H) atoms. Alkali An alkali is a soluble salt of an alkali metal like sodium or potassium. Originally, the alkalis used in soapmaking were obtained from the ashes of plants, but they are now made commercially. Today, the term alkali describes a substance that chemically is a base (the opposite of an acid) and that reacts with and neutralizes an acid. The common alkalis used in soapmaking are sodium hydroxide (NaOH), also called caustic soda; and potassium hydroxide (KOH), also called caustic potash. How Soaps are Made Saponification of fats and oils is the most widely used soapmaking process. This method involves heating fats and oils and reacting them with a liquid alkali to produce soap and water (neat soap) plus glycerine. The other major soapmaking process is the neutralization of fatty acids with an alkali. Fats and oils are hydrolyzed (split) with a high-pressure steam to yield crude fatty acids and glycerine. The fatty acids are then purified by distillation and neutralized with an alkali to produce soap and water (neat soap). When the alkali is sodium hydroxide, a sodium soap is formed. Sodium soaps are "hard" soaps. When the alkali is potassium hydroxide, a potassium soap is formed. Potassium soaps are softer and are found in some liquid hand soaps and shaving creams. The carboxylate end of the soap molecule is attracted to water. It is called the hydrophilic (water-loving) end. The hydrocarbon chain is attracted to oil and grease and repelled by water. It is known as the hydrophobic (water-hating) end. How Water Hardness Affects Cleaning Action Although soap is a good cleaning agent, its effectiveness is reduced when used in hard water. Hardness in water is caused by the presence of mineral salts - mostly those of calcium (Ca) and magnesium (Mg), but sometimes also iron (Fe) and manganese (Mn). The mineral salts react with soap to form an insoluble precipitate known as soap film or scum. Soap film does not rinse away easily. It tends to remain behind and produces visible deposits on clothing and makes fabrics feel stiff. It also attaches to the insides of bathtubs, sinks and washing machines. Some soap is used up by reacting with hard water minerals to form the film. This reduces the amount of soap available for cleaning. Even when clothes are washed in soft water, some hardness minerals are introduced by the soil on clothes. Soap molecules are not very versatile and cannot be adapted to today's variety of fibers, washing temperatures and water conditions. A detergent is an effective cleaning product because it contains one or more surfactants. Because of their chemical makeup, the surfactants used in detergents can be engineered to perform well under a variety of conditions. Such surfactants are less sensitive than soap to the hardness minerals in water and most will not form a film. Detergent surfactants were developed in response to a shortage of animal and vegetable fats and oils during World War I and World War II. In addition, a substance that was resistant to hard water was needed to make cleaning more effective. At that time, petroleum was found to be a plentiful source for the manufacture of these surfactants. Today, detergent surfactants are made from a variety of petrochemicals (derived from petroleum) and/or oleochemicals (derived from fats and oils). Petrochemicals and Oleochemicals Like the fatty acids used in soapmaking, both petroleum and fats and oils contain hydrocarbon chains that are repelled by water but attracted to oil and grease in soils. These hydrocarbon chain sources are used to make the water-hating end of the surfactant molecule. Other Chemicals Chemicals, such as sulfur trioxide, sulfuric acid and ethylene oxide, are used to produce the water-loving end of the surfactant molecule. Alkalis As in soapmaking, an alkali is used to make detergent surfactants. Sodium and potassium hydroxide are the most common alkalis. How Detergent Surfactants Are Made Anionic Surfactants The chemical reacts with hydrocarbons derived from petroleum or fats and oils to produce new acids similar to fatty acids. A second reaction adds an alkali to the new acids to produce one type of anionic surfactant molecule. Nonionic Surfactants Nonionic surfactant molecules are produced by first converting the hydrocarbon to an alcohol and then reacting the fatty alcohol with ethylene oxide. These nonionic surfactants can be reacted further with sulfur-containing acids to form another type of anionic surfactant. HOW SOAPS AND DETERGENTS WORK These types of energy interact and should be in proper balance. Let's look at how they work together. Let's assume we have oily, greasy soil on clothing. Water alone will not remove this soil. One important reason is that oil and grease present in soil repel the water molecules. Now let's add soap or detergent. The surfactant's water-hating end is repelled by water but attracted to the oil in the soil. At the same time, the water-loving end is attracted to the water molecules. These opposing forces loosen the soil and suspend it in the water. Warm or hot water helps dissolve grease and oil in soil. Washing machine agitation or hand rubbing helps pull the soil free. What products, equipment and knowledge do I need to start making soap on a Large scale? Why Should You Have The Proper Tools? Why Should You Have A Plan? How important are the tools of your trade? Why is the proper equipment critical? What about your own time in dealing with an inefficient method? Can you take this time and focus it into sales? Would it be worthwhile? Why these materials and methods? Why not use silicone liners or molds? Why not sheet plastic liners? Why not Plexiglas? Why not larger tray molds? Does your soap making equipment work only with Cold Processed soap? How does one determine the batch size? Electricity Can you also tell us about electricity requirements on your soap making equipment so we can calculate local electricity cost to us. I use 220 voltage, common in Asia/Africa etc? Bars Per Week When we talk about number of bars per week, is it a 5 day week, 6 day week or 7 day week? Water Do you have any idea about water consumption needed to make about 20,000 bars a week? Bar Size What do you recommend is a good bar size? Temperature At what temperature should soap be mixed? What shapes do you make? How do you adjust the depth for the Cylinder, Cuber and Tablet molds? Are replacements parts available? How many molds would you need if you only offered one size? How do you clean the press and surrounding material? What is the press & molds manufactured of? Plastic, steel, silicone, etc? What products, equipment and knowledge do I need to start making cold processed soap on a Large scale? What is the best height to fill the water to in the jacket of the Oil-Wax Heater (Melter)? As a time saver, can I premix my oils in the heater and use them up over a period of a week or more? Can the oils be reheated each day or continuously left at 110 degrees without unacceptable degradation of the oils? Does the Oil-Wax Heater (Melter) maintain a constant temperature at the level required? In my region, our electricity is based on 220V. Will this be a problem in using your 15-gallon, Oil-Wax Heater (Melter) with the 110 volt heat/thermostat, since they will be coming from the ______? Is it possible to mix the base oils, water and lye for tracing in the Oil-Wax Heater (Melter)? When making CP soap, can we add the essential or fragrance oils into your 15 gallon Oil-Wax Heater (Melter) s? Will I need a pump connected to the Oil-Wax Heater (Melter) for direct pouring into my molds? What is a Ball Valve? Could you please tell me if your Oil-Wax Heater (Melter) s have the capacity to heat beeswax as well? Does your Oil-Wax Heater (Melter) Thermostat read in both Celsius and Fahrenheit? I notice that your Oil-Wax Heater (Melter) are double jacketed and that I must keep water in the outer jacket. What happens if I don’t always pay attention to this? Do you have and will you install timers on your Oil-Wax Heater (Melter) for automatic turn on? How much oil/water is left at the bottom of the tank when it is drained? Types of Soap Molds... Acrylic plastic: You see people popping up every several years who make these and then they fade away. They really don't release any easier than HDPE but they look pretty. Eventually, under lots of use, they break down and start cracking from the oils used in making soap, specifically the essential and fragrance oils. It is a real disservice to the unaware SoapMaker who has spent good money purchasing these. We used to make them for ourselves and when we found out what would happen under constant use, went to HDPE. The fragrance and essential oils, eventually start degrading the plastic, gradually working into it until it starts cracking. Wood: Has to have some sort of liner. Breaks down over time, warps, does not stand up to professional, repeated use and will eventually have to be replaced. Stainless Steel: Next to HDPE, this is the best but it is expensive both in labor and material. It also has to be insulated very well to maintain an even saponification. How long will it take for the soaps to saponify enough in an Air Soap Cutter Mold, where it can be de-molded? How long will it take for the soaps to saponify enough in a Manual Soap Cutter Mold, where it can be de-molded? What is the maximum number of pounds for an efficient easy to handle and cut, block of soap in your Manual Soap Cutter? Why are the molds for the Air Soap Cutter and Manual Soap Cutter in big blocks? Is it true that block molds provide better saponification? The soap molds are sure a challenge to put together. Will they be easier to fit together as time goes on? I am having trouble getting my Air Soap Cutter mold bottom into the groove? How long do you wait to cut after de-molding? What do you recommend for lining your soap molds? Isn't it a hassle lining soap molds? How do you stop soap molds from leaking? Do you line the soap molds, or is there something that seals the edges? What type of material do you use for the single bar soap molds? Is there any way to reduce my drying time? How do you move the trays around? How high can you stack the trays? Do you have vented trays? How do you know what size tray to use? How many bars of soap should I expect to be able to stack on a single vented drying tray? You have equipment for liquid soapmaking. What is that please? Do you have lye tanks? In case of a large production, can you tell me how to solve the problem of lye fumes? Will I need a pump connected to the Oil-Wax Heater (Melter) for direct pouring into my molds? Can I use your Oil-Wax Heater (Melter) for Candle wax? Can you set an Oil Heater or Lye Tank at a particular set point and will it maintain that temperature? What is the difference between the Soap Cutter with a loaf grid and the Soap Cutter with a bar grid? Does the Air Soap Cutter cut in logs and bars or only one type? I recently received your Air Soap Cutter and Soap Molds. The base plate for the bar cutter appears to be bowed. It still fits on the pins but it has some rocking to it. Is this a problem? How many frames come with the Air Soap Cutter? Does the Manual Cutter work with the small Professional Mold? Can the size of the Manual Soap Cutter grid be made to fit the size of our soaps (3.5 x 1 x 2.4 inches)? What is the difference between the Manual Soap Cutter with a loaf grid and the Manual Soap Cutter with a bar grid? Does the Manual Soap Cutter and Air Soap Cutter cut in logs and bars or only one type? I recently received your Manual Soap Cutter and Soap Molds. The base plate for the bar cutter appears to be bowed. It still fits on the pins but it has some rocking to it. Is this a problem? You mentioned that the air soap cutter mold is grooved on the bottom so that the cutter wires can pass all the way through the block. What happens with the Manual Soap Cutter, where there is no groove? Are you left with a little uncut bit at the bottom of the stroke? Does the bar cut frame cut one log at a time, or a bunch of logs? Will the Manual Cutter cut soap from slab or tray molds? How do you go about mixing the sodium hydroxide with the water for such big batches of soap? When must soaps be cut? Can you give me some advice on soap coloring and swirling? I want to produce soap in large quantities but in single molds with a 3D look and hopefully with a logo. Would this be cost effective? The drying racks are wonderful, but from there should they (Soap Bars) be in cardboard, plastic, bins, open, or closed or what? How long will it take for the soaps to saponify enough in an Air Soap Cutter Mold, where it can be de-molded? How long will it take for the soaps to saponify enough in a Manual Soap Cutter Mold, where it can be de-molded? What is the maximum number of pounds for an efficient easy to handle and cut, block of soap in your Manual Soap Cutter? Why are the molds for the Air Soap Cutter and Manual Soap Cutter in big blocks? Is it true that block molds provide better saponification? The soap molds are sure a challenge to put together. Will they be easier to fit together as time goes on? I am having trouble getting my Air Soap Cutter mold bottom into the groove? How long do you wait to cut after de-molding? What do you recommend for lining your soap molds? Isn't it a hassle lining soap molds? How do you stop soap molds from leaking? Do you line the soap molds, or is there something that seals the edges? How many bars can I stamp at a time using your Soap Stamper? How long can I wait before stamping my soaps and how difficult do you think it will be? How long will it take to pay for the Stamper and how much should I figure in cost per bar for stamping? Does your software soapmaker pro also show cost for lotion making?. Can I add additives, oils, etc. to the software program? How do I delete ingredients I don't want? Additives I have a lot of additives - is there any way I can categorize them in the ingredients list? Here are further guidelines. |

Detergents

A detergent is a surfactant or a mixture of surfactants with "cleaning properties in dilute solutions. Powder and liquid detergent can be used for other purposes besides cleaning clothes or dishes. Major applications of detergents Laundry detergents Fuel additives Biological reagent Soapless soap Uses Detergents are mainly used in products for personal hygiene, dishwashing, and laundry. In addition, detergents are often added to a variety of products, to prevent the buildup of undesirable deposits. Some products that may contain detergents include: •toothpastes •antiseptic agents •dry-cleaning solutions •gasoline •lubricating oils |

Body Wash

|

Body Wash Fragrance Collection Sweet Honeysuckle & Orange Peel

Water Sodium Chloride Tetrasodium EDTA Fragrance Sodium Hydroxide Sodium Laureth Sulfate Acrylates Copolymer Cocamidopropyl Betaine DMDM Hydantoin Butyrospermum Parkii (Shea Butter) Zea Mays (Corn) Oil Lonicera Japonica (Honeysuckle) Flower Extract Citrus Aurantium Dulcis (Orange) Peel Extract Gelatin Acacia Senegal Gum Mica Citric Acid Xanthan Gum Titanium Dioxide FD&C Yellow No. 6 |

Liquid Hand Soap

|

Liquid Hand Soap Liquid Hand Soap Refill Skin Care | Cleansing | Liquid Hand Soap Liquid hand soap brands  Softsoap Dial Yes to Cucumbers Liquid Hand Soap Yes to Grapefruit Liquid Hand Soap Yes to Blueberries Liquid Hand Soap Caldrea Liquid Hand Soap Lava Heavy Duty Hand Cleaner Liquid Soap   Softsoap Hand Soap, Peony and Plum Peony & Plum Ingredients Water Sodium chloride Tetrasodium EDTA Sodium C14-16 olefin sulfonate Laureth-3 Cocamidopropyl betaine Fragrance DMDM hydantoin Citric acid Polyquaternium-7 Aloe barbadensis leaf juice Glycerin Poloxamer 124 Hydrolyzed silk D&C red no. 33 FD&C blue no. 1 |