|

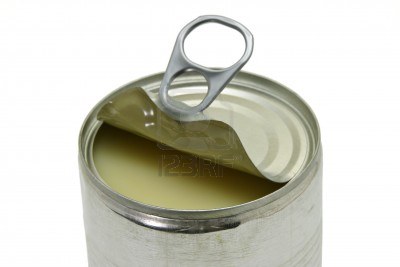

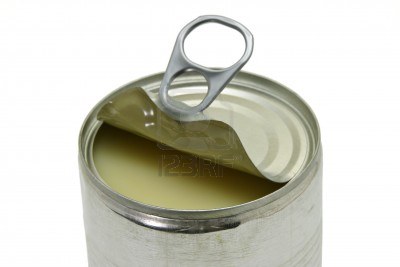

| Raw milk is clarified and standardised, and is then heated to 85–90 °C (185–194 °F) for several seconds. This heating process destroys some microorganisms, decreases fat separation and inhibits oxidation. Some water is evaporated from the milk and sugar is added until a 9:11 (Nearly half) ratio of sugar to (evaporated) milk is reached. The sugar extends the shelf life of sweetened condensed milk. Sucrose increases the liquid's osmotic pressure, which prevents microorganism growth. The sweetened evaporated milk is cooled and lactose crystallization is induced. |