|

Electricity Chief Engineer PDD Kashmir/NHPC/Commissioner/Central Electricity Regulatory Authority Please write a report on the topic, "Why is it possible to have electricity 24/7 in Canada and not possible in Kashmir?" What are the merits and demerits of having a similar system in Kashmir? Why isn't 24/7 electricity possible now while it previously was possible? Why isn't 24/7 electricity possible now while it was possible at other time periods? Can you describe the existing power structure in Kashmir? How is it connected to a central regulatory authority? What are the existing proposals for enhancing the electricity? Which companies or persons were involved in previous projects? How much did each project cost? How did they get the payments? How was the figure calculated? Who were involved? What are your requirements? How will advance payments be made? |

Hydro Electric Projects

Hydro Electric Projects

Receiving stations Transformers |

|

Nuclear Power Plants |

| Power transmission line materials. |

| From points of generation to points of demand. |

| Guidance for Electrical Engineer |

| Guidance for Electrician |

| Guidance for Electricity Department |

| Guidance for Electrical Equipment Manufacturers |

|

Q) Would you like to add anything? Q) Can you make me wiser? How? Q) Can you make us wiser? How? Q) Do you have any recommendations? Take a look at this Do you want me to make them competent? What's their contact information? Whose compliance do I need to complete this project? Who has the duty and responsibility to assist, to provide resources? If he/she/they don't comply, what do I have to do? Does education enhance the economy? Yes. How will advance payments be made?     Hydro Electric Projects

Q) What is the average cost of operating and maintaining a hydroelectric project? Q) What will it look like? Q) Do you have a Map? Q) Do You Have a Road Map? Q) Do you have map data in digital form? Q) How was the Map produced? Q) Who uses the Map and why? Q) Why do you need to update the map? Q) How accurate is the data? Q) What is a Topographic Map? Q) What information can I find on a topographic map? Q) When Can We Start the Construction and How Long Will It Take? Q) How was the budget figure reached? Q) What types of information are required but not available? Q) Are all of the required dimensions shown? Q) Are all necessary explanatory notes given? Q) Are all general notes in their proper location on the drawing? |

| Electricity Asia |

| Electricity Africa |

| Electricity America |

| Electricity Europe |

| Electricity Latin America |

| Electricity Australia |

|

Worldwide, hydropower plants produce about 24 percent of the world's electricity and supply more than 1 billion people with power. The world's hydropower plants output a combined total of 675,000 megawatts, the energy equivalent of 3.6 billion barrels of oil.

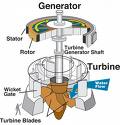

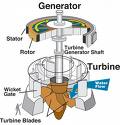

Hydropower plants harness water's energy and use simple mechanics to convert that energy into electricity. Hydropower plants are actually based on a rather simple concept -- water flowing through a dam turns a turbine, which turns a generator. Here are the basic components of a conventional hydropower plant: Dam - Most hydropower plants rely on a dam that holds back water, creating a large reservoir. Often, this reservoir is used as a recreational lake, such as Lake Roosevelt at the Grand Coulee Dam in Washington State. Intake - Gates on the dam open and gravity pulls the water through the penstock, a pipeline that leads to the turbine. Water builds up pressure as it flows through this pipe. Turbine - The water strikes and turns the large blades of a turbine, which is attached to a generator above it by way of a shaft. The most common type of turbine for hydropower plants is the Francis Turbine, which looks like a big disc with curved blades. A turbine can weigh as much as 172 tons and turn at a rate of 90 revolutions per minute (rpm), according to the Foundation for Water & Energy Education (FWEE). Generators - As the turbine blades turn, so do a series of magnets inside the generator. Giant magnets rotate past copper coils, producing alternating current (AC) by moving electrons. (You'll learn more about how the generator works later.) Transformer - The transformer inside the powerhouse takes the AC and converts it to higher-voltage current. Heavy electric transformers, power stabilizers and UPS units, Power lines - Out of every power plant come four wires: the three phases of power being produced simultaneously plus a neutral or ground common to all three. (Read How Power Distribution Grids Work to learn more about power line transmission.) Outflow - Used water is carried through pipelines, called tailraces, and re-enters the river downstream. The water in the reservoir is considered stored energy. When the gates open, the water flowing through the penstock becomes kinetic energy because it's in motion. The amount of electricity that is generated is determined by several factors. Two of those factors are the volume of water flow and the amount of hydraulic head. The head refers to the distance between the water surface and the turbines. As the head and flow increase, so does the electricity generated. The head is usually dependent upon the amount of water in the reservoir. Pumped-Storage Plants There's another type of hydropower plant, called the pumped-storage plant. In a conventional hydropower plant, the water from the reservoir flows through the plant, exits and is carried down stream. A pumped-storage plant has two reservoirs: Upper reservoir - Like a conventional hydropower plant, a dam creates a reservoir. The water in this reservoir flows through the hydropower plant to create electricity. Lower reservoir - Water exiting the hydropower plant flows into a lower reservoir rather than re-entering the river and flowing downstream. Using a reversible turbine, the plant can pump water back to the upper reservoir. This is done in off-peak hours. Essentially, the second reservoir refills the upper reservoir. By pumping water back to the upper reservoir, the plant has more water to generate electricity during periods of peak consumption. The Generator The heart of the hydroelectric power plant is the generator. Most hydropower plants have several of these generators. Photo courtesy U.S. Bureau of Reclamation The giant generators at Hoover Dam produce more than 2,000 megawatts. The generator, as you might have guessed, generates the electricity. The basic process of generating electricity in this manner is to rotate a series of magnets inside coils of wire. This process moves electrons, which produces electrical current. Inside a hydropower plant generator The Hoover Dam has a total of 17 generators, each of which can generate up to 133 megawatts. The total capacity of the Hoover Dam hydropower plant is 2,074 megawatts. Each generator is made of certain basic parts: Shaft Excitor Rotor Stator As the turbine turns, the excitor sends an electrical current to the rotor. The rotor is a series of large electromagnets that spins inside a tightly-wound coil of copper wire, called the stator. The magnetic field between the coil and the magnets creates an electric current. The largest hydroelectric power plant in the world can produce 12,600 megawatts. The second largest hydroelectric power plant can produce 10,300 megawatts. (Do you have better answer?) Hydropower plants take advantage of a naturally occurring, continuous process -- the process that causes rain to fall and rivers to rise. Every day, our planet loses a small amount of water through the atmosphere as ultraviolet rays break water molecules apart. But at the same time, new water is emitted from the inner part of the Earth through volcanic activity. The amount of water created and the amount of water lost is about the same. At any one time, the world's total volume of water is in many different forms. It can be liquid, as in oceans, rivers and rain; solid, as in glaciers; or gaseous, as in the invisible water vapor in the air. Water changes states as it is moved around the planet by wind currents. Wind currents are generated by the heating activity of the sun. Air-current cycles are created by the sun shining more on the equator than on other areas of the planet. |

What percentage of our energy comes from Hydro-electric?

I would like to know if there is a minimum requirement for the speed of the water as it is flowing to convert the energy to hydroelectricity. What are the minimum requirements to build a dam? Interesting questions.First, regarding the minimum water speed. It's not the speed of the water that's important, it's the volume, force and drop (the higher the drop and more volume, the more force). There are two main categories of hydroelectric power generation: conventional methods, which produce electricity via water flow in one direction (and are therefore dependent on seasonal runoff), and pumped storage methods, which are both producers and consumers of electricity as the water used to generate electricity can be recycled by pumping it back uphill. Two types of conventional hydroelectric facilities are dams and run-of-river. Dams raise the water level of a stream or river to an elevation necessary to create a sufficient elevation difference (water pressure, or head). Run-of-river, or water diversion, facilities typically divert water from its natural channel to run it through a turbine, and then usually return the water to the channel downstream of the turbine. Q. How much power can I generate with a hydroelectric turbine? A. The amount of power available depends on the dynamic head, which is a combination of the amount of water flow and the efficiency of the turbine generator. To get an idea about available power in watts, multiply the head in feet (total vertical drop), times flow in gallons per minute, times 0.18, times turbine efficiency. (For a rough estimate, use 30% efficiency for the turbine, see FAQ concerning efficiency below.) Q. How much water and pressure do I need for a small hydro system to work? A. In general, the more the better. Practically, you need at least 3 feet of fall with a 12 gpm water flow. If you have higher fall (pressure), you can get by with much less water. Q. Can you help with sizing? A. Yes, if you think you have a suitable site, contact us and we will help you choose the best unit for your situation. We will need to know the following information about your site: 1. Head: The total vertical elevation from the place where the water enters the pipe to the point where the turbine will be located. 2. Flow: The number of gallons per minute that are available. 3. Distance: The length of pipe that will be necessary to carry the water from the pickup to the turbine. If the pipe is already installed, what is the type and diameter? 4. Location: Distance from the turbine to the batteries. Q. What is turbine efficiency? A. Turbine efficiency ranges from 25% to 50%, with higher efficiency at higher heads. The Harris Pelton turbines are well suited to higher head and lower flow situations. Flow is limited by nozzle size (a maximum 1/2"). With the Harris, adjustment to variable flows is as easy as switching a valve and dialing in the alternator. Harris turbines are now available with permanent magnet (PM) alternators. This option provides up to 50% efficiency. Higher flows are accommodated by the ESD Turgo Turbines. They can have nozzles of up to 1" diameter, and provide better efficiency at low heads. The HI-Power Hydros are ideal for sites where water is available at long distances from power needs. They generate 100+volts AC that is stepped down and rectified at the batteries. This allows the use of relatively small wire for a distance of up to 10,000 feet. Transmitting the power from the generator to the battery at twice the battery voltage allows you to use 1/4 of the wire size for the same power loss. At 4 times the battery voltage, you can use 1/16 of the wire size required to transmit power at the battery voltage. The HI-Power hydroelectric generator can also deliver up to 3600 watts where higher power is needed. The LV Hydroelectric Generator and the ES&D Water Baby are good solutions for very low flow situations where the head is high enough to make some power. Q. What size and type of pipe do I need? A. Polyethylene pipe can be used for pressures up to 100 psi, PVC pipe is available with pressure ratings from 160 to 350 psi and steel pipe can withstand 1000 psi or more. Check with your local plumbing supplier for pipe ratings. Pipe diameter is very important. All pipelines will cause the water flowing in them to lose some energy to friction. The pipe must be large enough for the maximum quantity of water it will carry. Q. How do I determine how much pressure I have? A. A hydroelectric turbine operates from the pressure at the bottom end of a pipeline. This pressure, usually measured in pounds per square inch (psi), is directly related to the head, the vertical drop from the top of the pipeline to the bottom of the pipeline where the water goes into the turbine. The pressure at the lowest point of a pipeline is equal to 0.433 times the head, (the vertical distance in feet). Pressure is important because it is a determining factor in how much power is available and what type of pipe is required. Q. If I know the total head, how can I translate this into pressure. A. The basic formula is 2.31 psi = total head. Since you know the head, just divide by 2.31 for a psi (pounds per square inch) figure. Q. What is dynamic pressure and static pressure? A. The pressure at the bottom of a pipeline when water is not flowing is called static pressure. When water is flowing through the outlet or nozzle of the hydroelectric turbine, the pressure at the outlet is the dynamic pressure or running head. If you install a gate valve on the pipeline just above the turbine and a pressure gauge on a "T" fitting just above the gate valve, you will read the static pressure on the gauge when the valve is closed and the dynamic pressure when the valve is opened. The maximum power that can be delivered by a pipeline will occur when the dynamic pressure is approximately 2/3 of the static pressure. Q. What will be the actual flow rate of the water? A. The actual flow rate of the water in a hydroelectric system is determined by the diameter of the nozzle. We can supply a turbine with the proper size nozzle for your site, depending on the head, flow, length and diameter of the pipe. Q. How do I select a nozzle? A. Power out of a hydroelectric generator is determined by the pressure of the water at the nozzle and the amount of water flowing out of the nozzle. The larger the nozzle, the greater the flow. The nozzle must also be sized small enough to keep your pipeline full and keep the speed of the water in the pipe below 5' per second. The nozzle selection chart below shows water flow through various size nozzles at given pressures. Use this chart to determine what size nozzle and how many nozzles you need to accommodate the flow of water you have and to deliver the amount of power you need. A pressure gauge in the pipe feeding your turbine, installed before the shutoff valve, can help you check proper operation and diagnose problems. When the valve is shut off, the gauge will read the static pressure in pounds per square inch psi (head in feet x .433). When the valve is turned on the gauge will read a lower (dynamic) pressure. The difference between these two pressures represents your loss to friction in the pipe. The greater the flow, the greater your loss. (See PVC pipe loss chart below). Q. When the hydro site is located more than 300 feet from the house, is it better to use a higher voltage, AC system? A. If there's lots of water power available, and the alternator rpm changes relatively slowly, it seems better to send well-regulated 120/240VAC, with the shunt regulator inside the house, with a lightning arrestor in series, but no batteries or inverters, and use the excess power for heating water, etc. Some water wheels are more controllable than others. A Pelton wheel with no load might run 6 times faster than under full load, but other types might only run 20% faster. Worldwide, hydropower plants produce about 24 percent of the world's electricity and supply more than 1 billion people with power. The world's hydropower plants output a combined total of 675,000 megawatts, the energy equivalent of 3.6 billion barrels of oil. Hydropower plants harness water's energy and use simple mechanics to convert that energy into electricity. Hydropower plants are actually based on a rather simple concept -- water flowing through a dam turns a turbine, which turns a generator. Here are the basic components of a conventional hydropower plant: Dam - Most hydropower plants rely on a dam that holds back water, creating a large reservoir. Often, this reservoir is used as a recreational lake, such as Lake Roosevelt at the Grand Coulee Dam in Washington State. Intake - Gates on the dam open and gravity pulls the water through the penstock, a pipeline that leads to the turbine. Water builds up pressure as it flows through this pipe. Turbine - The water strikes and turns the large blades of a turbine, which is attached to a generator above it by way of a shaft. The most common type of turbine for hydropower plants is the Francis Turbine, which looks like a big disc with curved blades. A turbine can weigh as much as 172 tons and turn at a rate of 90 revolutions per minute (rpm), according to the Foundation for Water & Energy Education (FWEE). Generators - As the turbine blades turn, so do a series of magnets inside the generator. Giant magnets rotate past copper coils, producing alternating current (AC) by moving electrons. (You'll learn more about how the generator works later.) Transformer - The transformer inside the powerhouse takes the AC and converts it to higher-voltage current. Heavy electric transformers, power stabilizers and UPS units, Power lines - Out of every power plant come four wires: the three phases of power being produced simultaneously plus a neutral or ground common to all three. (Read How Power Distribution Grids Work to learn more about power line transmission.) Outflow - Used water is carried through pipelines, called tailraces, and re-enters the river downstream. The water in the reservoir is considered stored energy. When the gates open, the water flowing through the penstock becomes kinetic energy because it's in motion. The amount of electricity that is generated is determined by several factors. Two of those factors are the volume of water flow and the amount of hydraulic head. The head refers to the distance between the water surface and the turbines. As the head and flow increase, so does the electricity generated. The head is usually dependent upon the amount of water in the reservoir. Pumped-Storage Plants There's another type of hydropower plant, called the pumped-storage plant. In a conventional hydropower plant, the water from the reservoir flows through the plant, exits and is carried down stream. A pumped-storage plant has two reservoirs: Upper reservoir - Like a conventional hydropower plant, a dam creates a reservoir. The water in this reservoir flows through the hydropower plant to create electricity. Lower reservoir - Water exiting the hydropower plant flows into a lower reservoir rather than re-entering the river and flowing downstream. Using a reversible turbine, the plant can pump water back to the upper reservoir. This is done in off-peak hours. Essentially, the second reservoir refills the upper reservoir. By pumping water back to the upper reservoir, the plant has more water to generate electricity during periods of peak consumption. The Generator The heart of the hydroelectric power plant is the generator. Most hydropower plants have several of these generators. Photo courtesy U.S. Bureau of Reclamation The giant generators at Hoover Dam produce more than 2,000 megawatts. The generator, as you might have guessed, generates the electricity. The basic process of generating electricity in this manner is to rotate a series of magnets inside coils of wire. This process moves electrons, which produces electrical current. Inside a hydropower plant generator The Hoover Dam has a total of 17 generators, each of which can generate up to 133 megawatts. The total capacity of the Hoover Dam hydropower plant is 2,074 megawatts. Each generator is made of certain basic parts: Shaft Excitor Rotor Stator As the turbine turns, the excitor sends an electrical current to the rotor. The rotor is a series of large electromagnets that spins inside a tightly-wound coil of copper wire, called the stator. The magnetic field between the coil and the magnets creates an electric current. The largest hydroelectric power plant in the world can produce 12,600 megawatts. The second largest hydroelectric power plant can produce 10,300 megawatts. (Do you have better answer?) Hydropower plants take advantage of a naturally occurring, continuous process -- the process that causes rain to fall and rivers to rise. Every day, our planet loses a small amount of water through the atmosphere as ultraviolet rays break water molecules apart. But at the same time, new water is emitted from the inner part of the Earth through volcanic activity. The amount of water created and the amount of water lost is about the same. At any one time, the world's total volume of water is in many different forms. It can be liquid, as in oceans, rivers and rain; solid, as in glaciers; or gaseous, as in the invisible water vapor in the air. Water changes states as it is moved around the planet by wind currents. Wind currents are generated by the heating activity of the sun. Air-current cycles are created by the sun shining more on the equator than on other areas of the planet. |

What percentage of our energy comes from Hydro-electric?

I would like to know if there is a minimum requirement for the speed of the water as it is flowing to convert the energy to hydroelectricity. What are the minimum requirements to build a dam? Interesting questions.First, regarding the minimum water speed. It's not the speed of the water that's important, it's the volume, force and drop (the higher the drop and more volume, the more force). There are two main categories of hydroelectric power generation: conventional methods, which produce electricity via water flow in one direction (and are therefore dependent on seasonal runoff), and pumped storage methods, which are both producers and consumers of electricity as the water used to generate electricity can be recycled by pumping it back uphill. Two types of conventional hydroelectric facilities are dams and run-of-river. Dams raise the water level of a stream or river to an elevation necessary to create a sufficient elevation difference (water pressure, or head). Run-of-river, or water diversion, facilities typically divert water from its natural channel to run it through a turbine, and then usually return the water to the channel downstream of the turbine. Q. How much power can I generate with a hydroelectric turbine? A. The amount of power available depends on the dynamic head, which is a combination of the amount of water flow and the efficiency of the turbine generator. To get an idea about available power in watts, multiply the head in feet (total vertical drop), times flow in gallons per minute, times 0.18, times turbine efficiency. (For a rough estimate, use 30% efficiency for the turbine, see FAQ concerning efficiency below.) Q. How much water and pressure do I need for a small hydro system to work? A. In general, the more the better. Practically, you need at least 3 feet of fall with a 12 gpm water flow. If you have higher fall (pressure), you can get by with much less water. Q. Can you help with sizing? A. Yes, if you think you have a suitable site, contact us and we will help you choose the best unit for your situation. We will need to know the following information about your site: 1. Head: The total vertical elevation from the place where the water enters the pipe to the point where the turbine will be located. 2. Flow: The number of gallons per minute that are available. 3. Distance: The length of pipe that will be necessary to carry the water from the pickup to the turbine. If the pipe is already installed, what is the type and diameter? 4. Location: Distance from the turbine to the batteries. Q. What is turbine efficiency? A. Turbine efficiency ranges from 25% to 50%, with higher efficiency at higher heads. The Harris Pelton turbines are well suited to higher head and lower flow situations. Flow is limited by nozzle size (a maximum 1/2"). With the Harris, adjustment to variable flows is as easy as switching a valve and dialing in the alternator. Harris turbines are now available with permanent magnet (PM) alternators. This option provides up to 50% efficiency. Higher flows are accommodated by the ESD Turgo Turbines. They can have nozzles of up to 1" diameter, and provide better efficiency at low heads. The HI-Power Hydros are ideal for sites where water is available at long distances from power needs. They generate 100+volts AC that is stepped down and rectified at the batteries. This allows the use of relatively small wire for a distance of up to 10,000 feet. Transmitting the power from the generator to the battery at twice the battery voltage allows you to use 1/4 of the wire size for the same power loss. At 4 times the battery voltage, you can use 1/16 of the wire size required to transmit power at the battery voltage. The HI-Power hydroelectric generator can also deliver up to 3600 watts where higher power is needed. The LV Hydroelectric Generator and the ES&D Water Baby are good solutions for very low flow situations where the head is high enough to make some power. Q. What size and type of pipe do I need? A. Polyethylene pipe can be used for pressures up to 100 psi, PVC pipe is available with pressure ratings from 160 to 350 psi and steel pipe can withstand 1000 psi or more. Check with your local plumbing supplier for pipe ratings. Pipe diameter is very important. All pipelines will cause the water flowing in them to lose some energy to friction. The pipe must be large enough for the maximum quantity of water it will carry. Q. How do I determine how much pressure I have? A. A hydroelectric turbine operates from the pressure at the bottom end of a pipeline. This pressure, usually measured in pounds per square inch (psi), is directly related to the head, the vertical drop from the top of the pipeline to the bottom of the pipeline where the water goes into the turbine. The pressure at the lowest point of a pipeline is equal to 0.433 times the head, (the vertical distance in feet). Pressure is important because it is a determining factor in how much power is available and what type of pipe is required. Q. If I know the total head, how can I translate this into pressure. A. The basic formula is 2.31 psi = total head. Since you know the head, just divide by 2.31 for a psi (pounds per square inch) figure. Q. What is dynamic pressure and static pressure? A. The pressure at the bottom of a pipeline when water is not flowing is called static pressure. When water is flowing through the outlet or nozzle of the hydroelectric turbine, the pressure at the outlet is the dynamic pressure or running head. If you install a gate valve on the pipeline just above the turbine and a pressure gauge on a "T" fitting just above the gate valve, you will read the static pressure on the gauge when the valve is closed and the dynamic pressure when the valve is opened. The maximum power that can be delivered by a pipeline will occur when the dynamic pressure is approximately 2/3 of the static pressure. Q. What will be the actual flow rate of the water? A. The actual flow rate of the water in a hydroelectric system is determined by the diameter of the nozzle. We can supply a turbine with the proper size nozzle for your site, depending on the head, flow, length and diameter of the pipe. Q. How do I select a nozzle? A. Power out of a hydroelectric generator is determined by the pressure of the water at the nozzle and the amount of water flowing out of the nozzle. The larger the nozzle, the greater the flow. The nozzle must also be sized small enough to keep your pipeline full and keep the speed of the water in the pipe below 5' per second. The nozzle selection chart below shows water flow through various size nozzles at given pressures. Use this chart to determine what size nozzle and how many nozzles you need to accommodate the flow of water you have and to deliver the amount of power you need. A pressure gauge in the pipe feeding your turbine, installed before the shutoff valve, can help you check proper operation and diagnose problems. When the valve is shut off, the gauge will read the static pressure in pounds per square inch psi (head in feet x .433). When the valve is turned on the gauge will read a lower (dynamic) pressure. The difference between these two pressures represents your loss to friction in the pipe. The greater the flow, the greater your loss. (See PVC pipe loss chart below). Q. When the hydro site is located more than 300 feet from the house, is it better to use a higher voltage, AC system? A. If there's lots of water power available, and the alternator rpm changes relatively slowly, it seems better to send well-regulated 120/240VAC, with the shunt regulator inside the house, with a lightning arrestor in series, but no batteries or inverters, and use the excess power for heating water, etc. Some water wheels are more controllable than others. A Pelton wheel with no load might run 6 times faster than under full load, but other types might only run 20% faster. Hydro Electric Projects

Q) What is the average cost of operating and maintaining a hydroelectric project? Q) What will it look like? Q) Do you have a Map? Q) Do You Have a Road Map? Q) Do you have map data in digital form? Q) How was the Map produced? Q) Who uses the Map and why? Q) Why do you need to update the map? Q) How accurate is the data? Q) What is a Topographic Map? Q) What information can I find on a topographic map? Q) When Can We Start the Construction and How Long Will It Take? Q) How was the budget figure reached? Q) What types of information are required but not available? Q) Are all of the required dimensions shown? Q) Are all necessary explanatory notes given? Q) Are all general notes in their proper location on the drawing?      Hydro Electric Projects

Hydro Electric Projects

Q) What is the average cost of operating and maintaining a hydroelectric project? Q) What will it look like? Q) Do you have a Map? Q) Do You Have a Road Map? Q) Do you have map data in digital form? Q) How was the Map produced? Q) Who uses the Map and why? Q) Why do you need to update the map? Q) How accurate is the data? Q) What is a Topographic Map? Q) What information can I find on a topographic map? Q) When Can We Start the Construction and How Long Will It Take? Q) How was the budget figure reached? Q) What types of information are required but not available? Q) Are all of the required dimensions shown? Q) Are all necessary explanatory notes given? Q) Are all general notes in their proper location on the drawing? Q) What is the method of payment? |